Use FloatBricks to build modular boat docks, floating platforms and walkways for commercial applications.

Trusted by leading organisations across Australia.

With FloatBricks, set up floating boat docks with ease, and expand with platforms or walkways as needed.

The modular design adapts to your needs, whether for a single boat or a larger setup.

No complex assembly, no high-maintenance parts.

FloatBricks: flexible docking made simple.

More than 500 Australian organisations choose FloatBricks for their on-water structures.

Easily reconfigure your FloatBricks to build different floating platforms.

Made from HDPE with no moving parts, our standard FloatBricks range needs virtually no maintenance.

Precise brick alignment equals a floating walkway with fewer trip hazards.

Over 50 years of combined experience in modular docking means we have the expertise to help with the most difficult projects.

Need a one-time platform or walkway? Ask us about hiring FloatBricks instead.

More than 500 Australian organisations choose FloatBricks for their on-water structures.

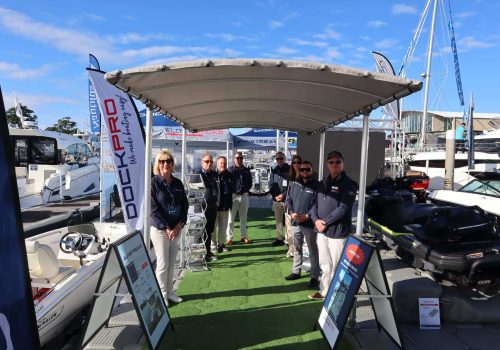

Talk through your floating walkway or platform requirements with a DOCKPRO commercial specialist.

1.

If FloatBricks is the right platform solution, your specialist will help you design a configuration that matches your budget, schedule, and use case.

2.

Once we’ve manufactured your bricks, our field technicians can deploy them at a site of your choice – or deliver them for a DIY installation.

3.

DOCKPRO & SeaPen have won multiple Gold Coast Business awards over the past two decades.

We are the first and only dry docking company winner of the most recognised award in the boating industry.

Innovanautica is a highly regarded award in Europe. We became finalist at our first attempt in 2023.

DockPro was honoured to win the Sustainability in the Boating Industry Award at the 2025 Sydney Boat Show.

FloatBricks makes operating on water easy – no long installation timelines, just a fully functional structure you can quickly set up.

Set up temporary work docks, jetties, or floating platforms with ease using FloatBricks.

Whether you’re creating boarding docks for passengers, transporting crews across wetlands, or supporting maintenance work, FloatBricks makes it simple.

Each anti-slip brick can be configured to handle various loads and equipped with handrails that meet Australian safety standards.

FloatBricks is designed for easy transport, stable support, and adaptability—keeping your projects safe, on time, and on budget.

Like any material, FloatBricks can become hot when exposed to a sufficient level of thermal energy. Unlike conventional platform materials like aluminium, timber, and steel, though, FloatBricks have a low thermal conductivity, which means they transfer heat to other surfaces – like shoes and feet – more slowly.

In other words: any structural material will get hot if you leave it in the sun for long enough. FloatBricks, though, are less hot to stand on than other types of platforms. If you do have personnel operating in extreme heat conditions, you can install T-Top Dock Covers on your platform to provide shade.

Yes, FloatBricks are suitable for building platforms in environments with tides, currents, and small waves. Because FloatBricks platforms are modular, they flex in synchronisation with water movement, which minimises the rougher ‘rocking’ motions associated with rigid structures (like boats).

Like all floating platforms, though, FloatBricks have limits. Their maximum wave height of 60 centimetres means that they can’t be used in extremely rough water or inclement weather.

FloatBricks are made from high-density polyethylene (HPDE), an industrial-grade thermoplastic that’s used for commercial piping and plastic lumber. Its high melting point, durability, and excellent stress resistance make it ideal for building on-water walkways and construction platforms.

Low-density polyethylene (LDPE) is a thermoplastic used by some manufacturers of floating bricks. Its main benefits are flexibility and cost, not strength or durability – which is why it’s normally used to make products like plastic bags and drink bottles. Its melting point is also almost 40% lower than HDPE, making it potentially unsuitable for certain commercial applications.

Exactly how your FloatBricks are secured depends on your environment and application. If you’re deploying a FloatBricks structure next to a fixed structure like a jetty or pier, you can secure it with variable-height brackets or mooring lines.

For personalised advice, schedule a consultation with one of our commercial specialists. They’ll help you design an appropriate configuration for your use case, which can include advice around options like swing moorings and anchors.

Get your project on the water with a FloatBricks platform or walkway.

Request A Quote

Form on the contact us page

"*" indicates required fields